HISTORY

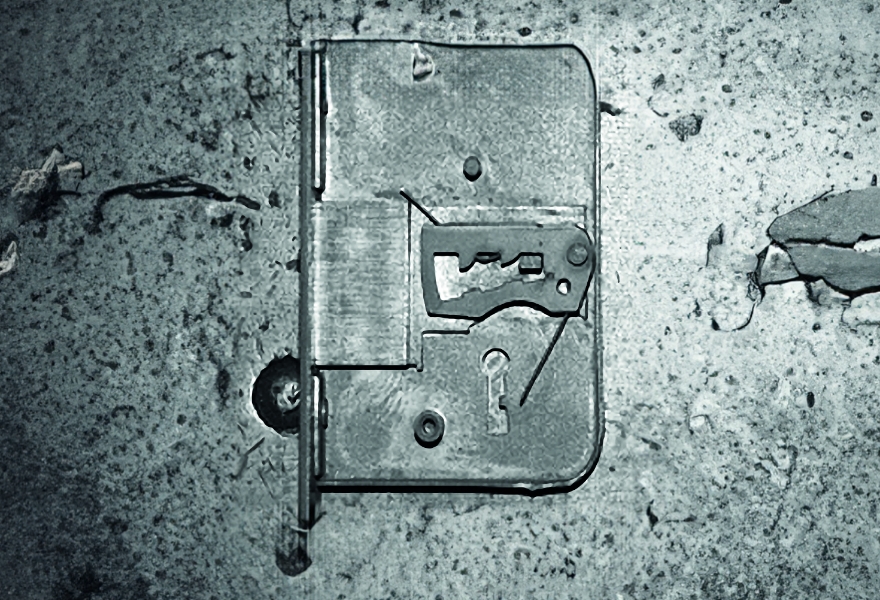

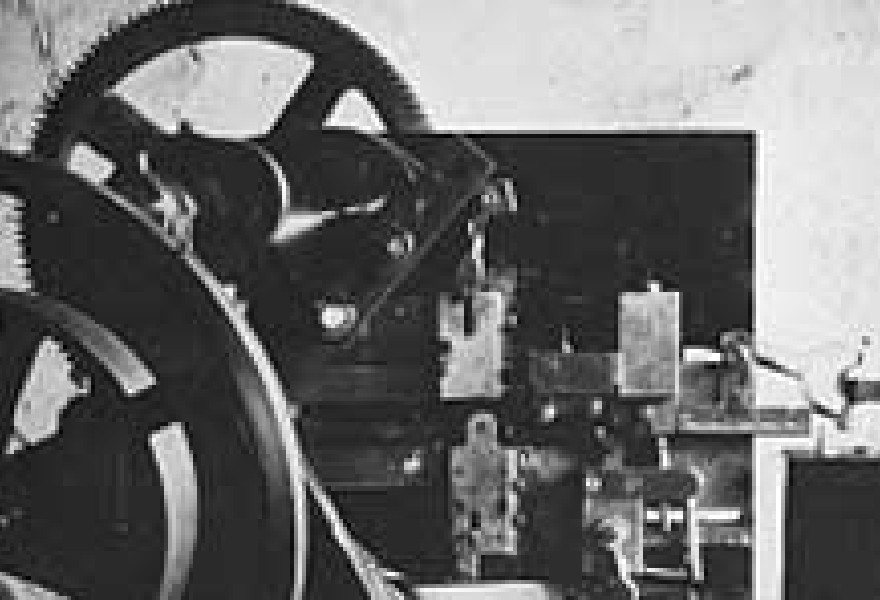

VITZFEDERN: A TRADITIONAL COMPANY WITH STYLEThe development of the small family business into a spring manufacturer is all thanks to contract work in the year 1908. At this time, a large locks factory commissioned mechanical engineer Johann Vitz and his four sons to create a machine to manufacture lock springs in order to optimise their work process. However, due to the fact that use of the machine could have ultimately led to the wives of the master craftsmen losing their jobs, a flimsy excuse was made to overrule machine production of the springs and, subsequently, use of the machines was rejected.

This all meant that the Vitz family had, on the one hand, an unexpected opportunity to produce the springs themselves, but had to deal with the loss of the contract on the other hand. The family business therefore took the offensive and sold the lock springs to the corresponding factories by itself. At the same time, they built more machines to manufacture other springs used in the lock industry at the time.

Spring production largely came to a standstill during the First World War due to the reduction in demand. The Vitz family’s inventiveness, however, did not wane: they developed a coal lighter operated by gas that could be used to ignite the poor quality coal, which was available for household use at that time.

The demand for springs grew enormously after the war. Above and beyond lock springs, there was a higher demand for compression, extension and torsion springs. The first machine not built by the company had to be purchased at the end of the 1920s as part of the expansion. The purchase of the company’s own premises also became necessary. The constant growth of the enterprise did not stop at the regional borders. Numerous Dutch and Belgian lock factories were soon added to the Velbert spring manufacturers’ customer portfolio.

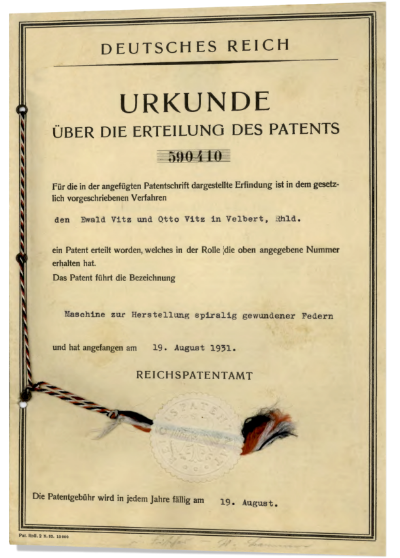

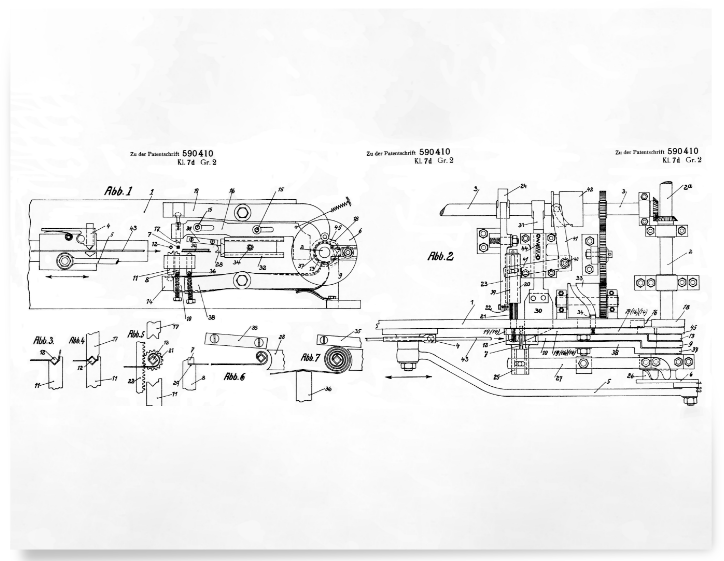

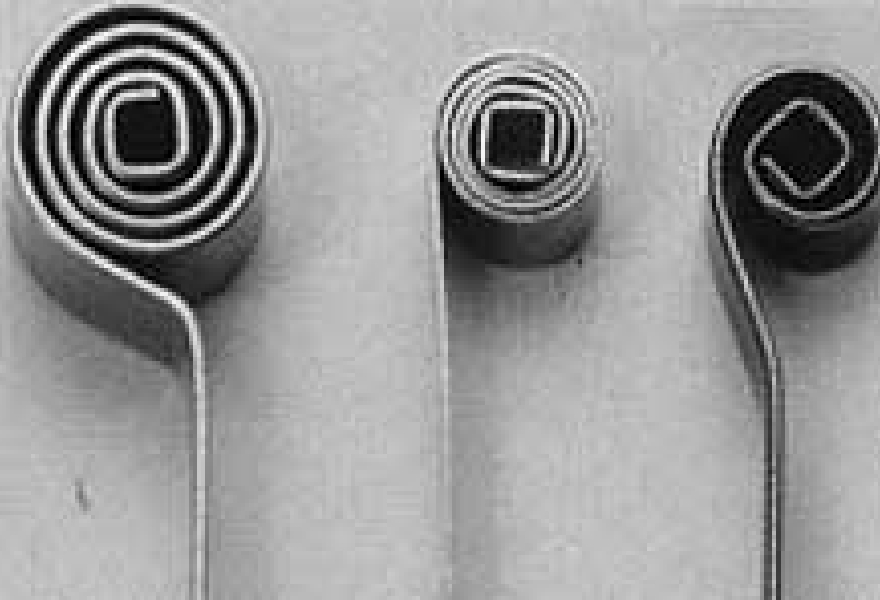

The lasting success gave Ewald and Otto Vitz the courage to optimise their manufacturing processes even further. They invented an improved a way of manufacturing lock springs, which was patented in 1931. The bicycle industry, followed by the automobile industry, became customers of the constantly expanding company.

This success continued up until the Second World War. At first, various supply parts (some using wage labour) were manufactured for regional companies, but at the end of the war production was stopped completely due to a lack of material and labourers. The company was hit in artillery fire. It was a miracle that Otto Vitz, who was alone on the premises at the time, was not injured.

Reconstruction proved to be extremely hard. However, the common goal of rebuilding Germany and its business structure even released unexpected strengths in tranquil Velbert. Refugees from the east regions and veterans returning from combat put all of their effort into the reconstruction of the spring manufacturing plant on Oststraße. And so the company’s success story has continued up to the present day.

The big break-through was triggered by the decision of Emil and Firedhelm Vitz, on the outskirts of Velbert, of building an new Company on the “green meadow” at the Uhlandstraße.

The development at the new Location was so rapid that the production halls were expanded at intervals of a few years. At the same time the company emphasized to produce at the most advances way. Therefore were always used the latest techniques and the range of products was extended with more exigent components.

Berthelm and Michael Vitz are the fourth generation of the grounder Johann Vitz. Michael Vitz acts since years as a Managing Partner. Berthelm Vitz died after several years of successful activity in 1988. His Family is now represented by Harald J. Gänz.